ENGINEERS at the University of Dundee are helping to silence the sound of offshore construction projects to preserve fragile ecosystems underwater.

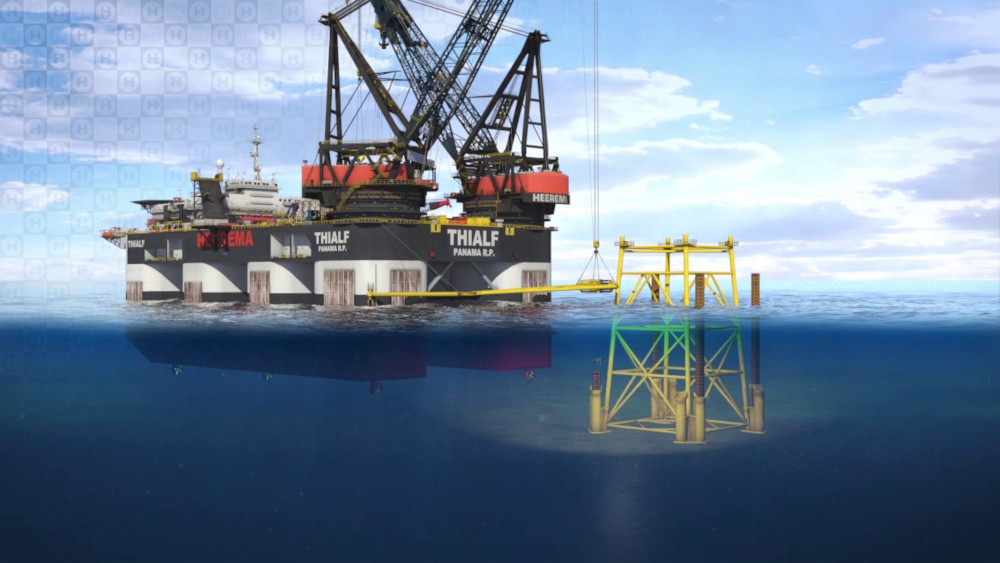

Members of the Geotechnical Engineering group have been assisting Heerema Marine Contractors in developing alternative means of installing foundations for offshore wind turbines.

The group has extensively tested and modelled concepts that would remove the need for loud underwater hammering, which can be harmful to marine life and require costly mitigation systems.

Professor Michael Brown, from Dundee’s School of Science and Engineering, said: “Our Geotechnical Engineering group has extensive experience in developing new foundation concepts for offshore renewable energy.

“We were approached by Heerema to further develop its concepts, utilising our world-leading experimental and physical testing facilities, developed as part of the Scottish Marine and Renewable Test Centre (SMART).

These testing facilities include the large geotechnical centrifuge testing centre, which is the only one of its kind in Scotland. We also used our physical modelling skills to conduct a comprehensive test regime for these designs.

“It is a huge honour to work with Heerema on such important work and is a testament to the expertise and facilities that we have here in Dundee that led to their initial approach.”

Offshore foundations are usually driven into the seabed using large hammers. This creates significant level of underwater noise and vibration upsetting the per-existing ecosystems.

These factors can be mitigated by using bubble curtains to reduce the level of noise passing through the water, though the effect of this is unpredictable and requires a vessel on site to pump compressed air into the area, bringing its own environmental cost.

Heerema has been working with the University of Dundee on two concepts: helical or screw piles, and so-called push-in piles, which can be installed without loud hammering and the subsequent need for mitigation measures.